Reading this in your email? For easier reading – Click here.

We at Green Mountain Timber Frames have a friend and fellow “restorationist” and we are very excited to be collaborating with him on a new project. It’s an incredible opportunity to preserve the “Amos Hodsdon House,” built in 1837.

Ben’s story

Meet Ben Heywood, center

Meet Ben – An Expert in Restoration

Ben Heywood moved into the area a few years ago after a career of preservation and restoration work in the Cape Cod area. Since moving to Vermont, he has become a friend as well as a consultant on some of our projects. He has aided us in assessing the fine details of houses dating from the 1800s. He has a wealth of knowledge regarding trim, window and door styles and the dating of buildings. He has done incredible work restoring original entryways, windows, and cupboards. On a recent weekend visit, I asked Ben how he got interested in restoration.

“I was born in Gardner, Massachusetts, in 1951. There were dozens of abandoned 18th and early 19th century houses in a 40 or 50 mile radius. In the course of many Sunday family rides in the station wagon, my father would drop me at these so I could snoop around. It was arranged that I’d be picked up about a half hour later. All kinds of different architecture… it was great! It took no time at all for me to understand the difference between the handcrafted specimens and the numerous postwar boxes popping up everywhere. I also bought and devoured all the Eric Sloane books by age 16. All this sent me in the preservation direction.”

Ben’s First Home Restoration

Ben moved to Falmouth and purchased his first “vintage” house in 1978 for the price of $1! It was a circa 1815 three quarter cape with a center hall and three fireplaces. It had the original doors, wainscot, finish trim and floors. As Ben told me, “I assembled some buddies and had it down in three weeks. I’ll never forget having to buy a liability policy from Lloyd’s of London as I was young and not yet firmly established. Insurance for four weeks cost me 500 times what I had paid for the house! Most everybody thought I was nuts at the time- until they saw the place restored!”

In the decades that followed, Ben disassembled and restored around 20 period houses. He did restoration in place on another 20!

Ben completed the restoration of the “Bodfish” house in 1982, which overlooks Cape Cod bay.

In 2008, Ben decided to find one last gem of a house that he would restore for himself as he moved to Vermont and into retirement. Enter: the remarkable house built by Amos Hodsdon in 1837.

The Hodsdon house, built in 1837

Now, due to life changes and a desire to downsize his construction plans, Ben has decided not to use this house as his own. The beautiful historic Hodson House is available for sale!

And we at Green Mountain Timber Frames want to help our friend find a new family to make this house into their home.

About the Vintage House

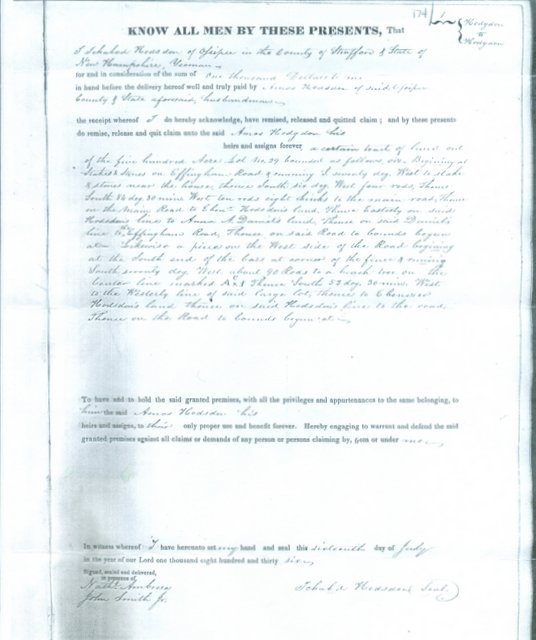

After looking at many vintage buildings, Ben decided on a house in Carroll County, New Hampshire, named after Charles Carroll who died in 1832 as the last surviving signer of the Declaration of Independence. Carroll County was created in 1840 with Ossipee as its seat. Ben learned this history lesson after his search of Carroll County deeds came up empty. Eventually, he realized that the county lines had changed three years after the deed to the property changed hands from father to son, and so was filed in Strafford County!

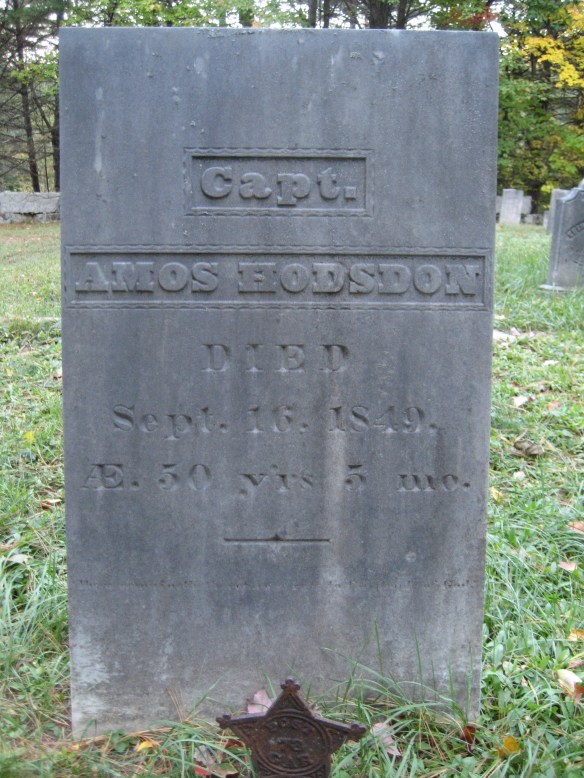

Ben found the gravestone of Captain Amos Hodsdon

Here is the deed showing the transfer of property from father to son

When Ben discovered the old Hodson place, the house was incredibly unaltered and in good “frame health,” for its age. It had been abandoned for ten years and had been occupied by an elderly couple before that. The kitchen had a typical cast iron sink mounted in what was surely a period dry sink. There was a rusty old spigot and pipe that ran into a tank heated by the wood stove! The last residents of the house had still been carrying water into the house from a six foot diameter dug well with a flat stone cover. Best of all… the house had never had a bathroom!

Ben assembled a crew and began dismantling the frame.

The roof boards come off

Here is a 46 foot purlin in the rafter system!

The exposed frame

The Frame Awaits a New Owner

Above you can see the tired entryway, and then the doorway after Ben’s incredibly meticulous restoration work.

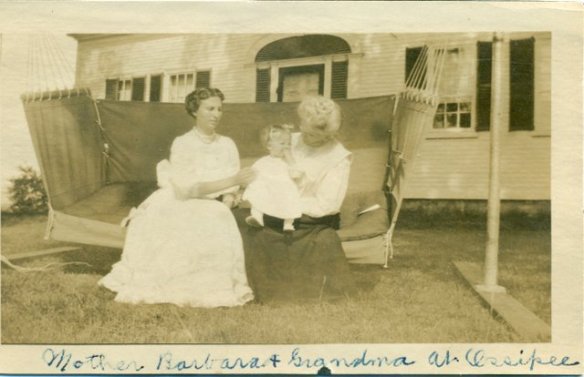

When the house came into Ben’s caretaking, the decorative fan work over the entrance had been removed and flat boards had been nailed up. Ben studied the “shadow lines,” which are marks and weathering patterns on the wood, in an attempt to figure out through detective work what the original had looked like. Then, in a fortuitous turn of events, a friend discovered this old photograph of the house. It confirmed Ben’s guess at what had graced the entrance originally, and wait till you see what he created!

This photo is the best rendition of the entranceway in the background. Oh, and the people in the foreground look fantastic too!!

Here you can see the incredible recreation of the decorative fan work over the doorway- all based on an early 1900’s photo!

Ben has even restored all the original windows!

This house boasts roughly 3,700 square feet of vintage living space. The crew at Green Mountain Timber Frames will do a complete restoration of the timber frame itself, and we are looking for someone who has always wanted to live in a beautiful New England style home!

Interested in this frame?

Know someone who may be able to help us find a home for this historical treasure? Please pass the word around that this wonderful structure is available and help us find a new “forever” location for this gem!

Contact us!

(802) 774-8972 or Luke@GreenMountainTimberFrames.com

As for the walls that are not made of glass, we covered them with traditional siding. The final structure is truly one-of-a-kind – made up of 70% glass – and allowing for a nearly unobstructed view of the surrounding woods.

As for the walls that are not made of glass, we covered them with traditional siding. The final structure is truly one-of-a-kind – made up of 70% glass – and allowing for a nearly unobstructed view of the surrounding woods.

The Diagonal Braces

The Diagonal Braces