Reading this in your email? For easier reading – Click here.

What is in a label?

When it comes to timber framing – a great deal!

The homes and historic barns that we disassemble have many individual pieces. A timber frame can easily have over two hundred different pieces of hand crafted wood and each piece has been carefully fit and adjusted to create a specific joint. Individual timbers and braces were scribed to each other. Braces in a building may look interchangeable, but they are not!

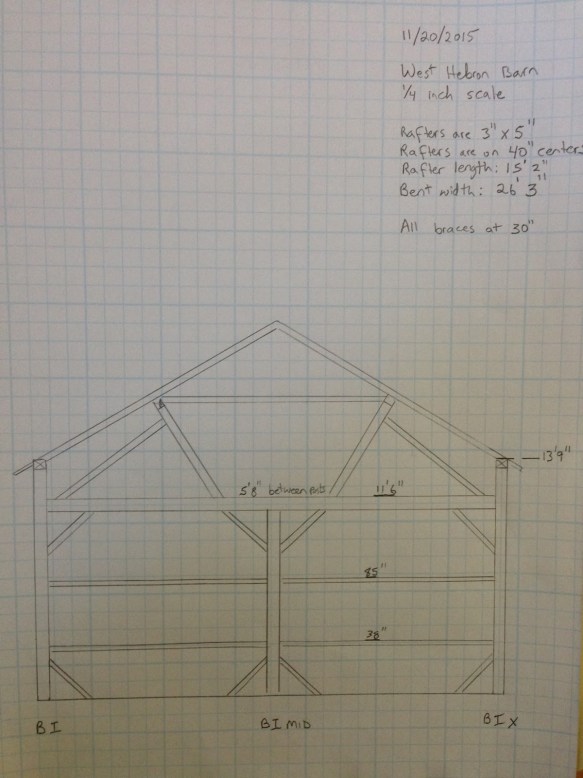

We use the terms “bent” and “plate wall” to describe the two types of cross sections in a barn. There are two plate walls in every timber frame, which are the exterior walls where the roof comes down.

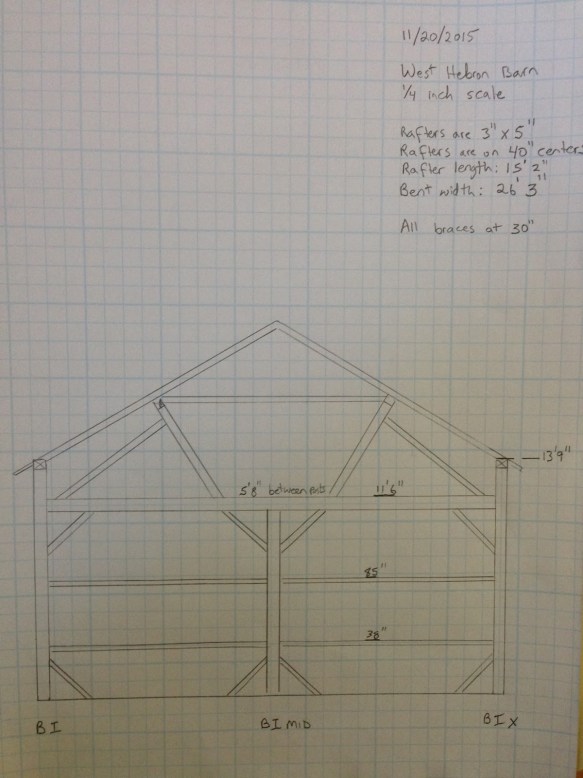

“Bents” are a cross section going in the other direction, creating the gable ends and supporting systems for the interior of the building. A frame can have anywhere from two bents to six or even more, depending on the barn size. Here is a scaled drawing of one bent cross section of an 1840s timber frame. This barn has four bents. Multiply this cross section by four and you can imagine the four bents, usually similar but not identical.  There are also the two eve walls with multiple braces, which can’t get mixed in with the “bent” braces!

There are also the two eve walls with multiple braces, which can’t get mixed in with the “bent” braces!  So how does one know where to put each piece of wood?

So how does one know where to put each piece of wood?

The labeling system!

History of Labeling Timber Frames

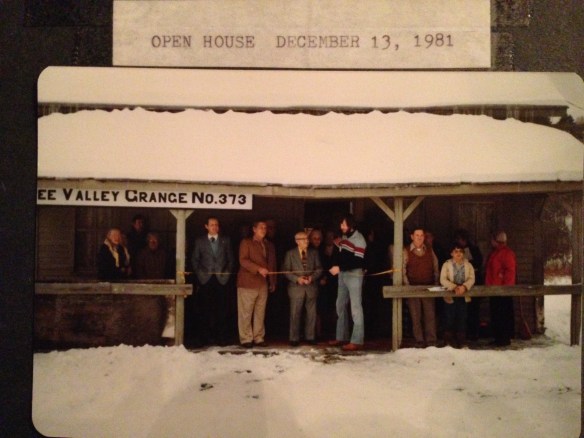

In many of the older barns and homes, even the roof boards and floorboards were labeled! Long before a crew of framers, farmers and family showed up for a house raising, someone had carefully organized the materials and designated a spot for each piece.

Why would it make sense to label even the roof boards?

One reason is that the boards were often still in the tapered shape of a tree trunk. In other words, they are wider at one end – the base of the tree – and narrower at the other. By switching the direction of the taper – board to board – as you moved up the roof, the framers could get the most width possible out of each board without getting too uneven before reaching the peak of the building.

Roman numerals were the most common method for inscribing labels on the beams and boards:

We recently completed the restoration of a 1790s gambrel home. (You can read about it in this blog.) This frame is a wonderful example of the way that craftsmen of the past insured that the timbers all ended up in the right place.

In the gambrel house we restored, there are four bents for a total of 12 posts on the first floor. There are 8 more on the second floor.

But how do you designate which side of the building each piece will live on?

Each exterior post is a component of both an eve wall, and a member of a bent. Therefore, each of the joint sections must be labeled. When we cut a new frame or relabel an old frame, we use “B” for bent, and “P” for plate, or eve wall. On top of this distinction, we distinguish which of the two eave walls any given post or brace belongs to.

In the gambrel, the original builders added a diagonal line to the numbers in order to make this distinction. This line makes post #4 look like this: Note the four slashes, and the one slash with an additional diagonal cut. The opposite wall does not have the diagonal marking.

Note the four slashes, and the one slash with an additional diagonal cut. The opposite wall does not have the diagonal marking.

Below is a label on a floor joist that had us stumped for a while. Then we realized – the framers were distinguishing the roman numeral 9- IX, from the roman numeral 11- XI. What if on raising day someone was looking at the floor joist upside down?

Joist #9 drops into the “summer beam”, the central heavy timber that supports the floor system.

Here is #11, not to be confused with #9!

We have not seen this marking before, but surmise that it meant 11. If anyone has seen this designation for 11 before, please tell us about it!

How do you designate that a post is a center post rather than located on an exterior wall?

Here is how they labeled an exterior mid post on the gambrel:

Someone took artistic care with this inscription!

And here is the label on an upper post that supports the rafter system. Notice our modern (and much less attractive) label on the tenon where it will be hidden: The gambrel has a unique system where the floor girts and joists went out beyond the eve to create an overhang. Heavy planks rested on the joist tails. Here is a photo of the labeling of those planks:

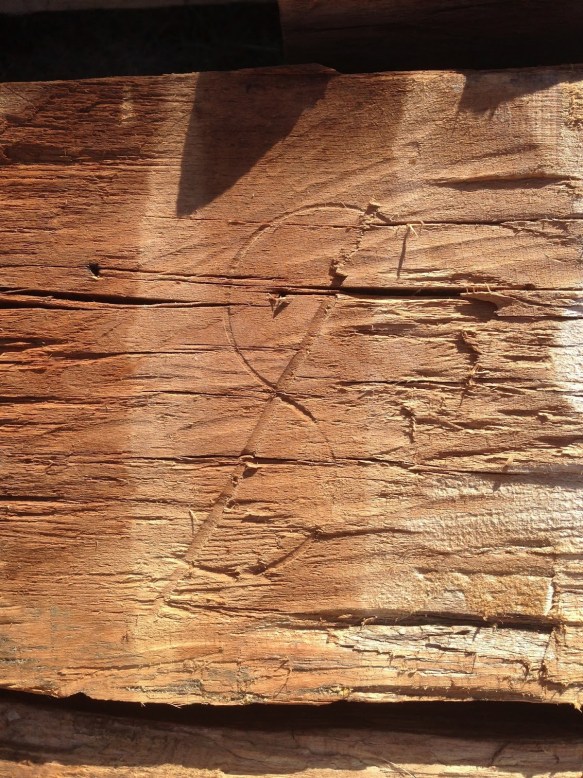

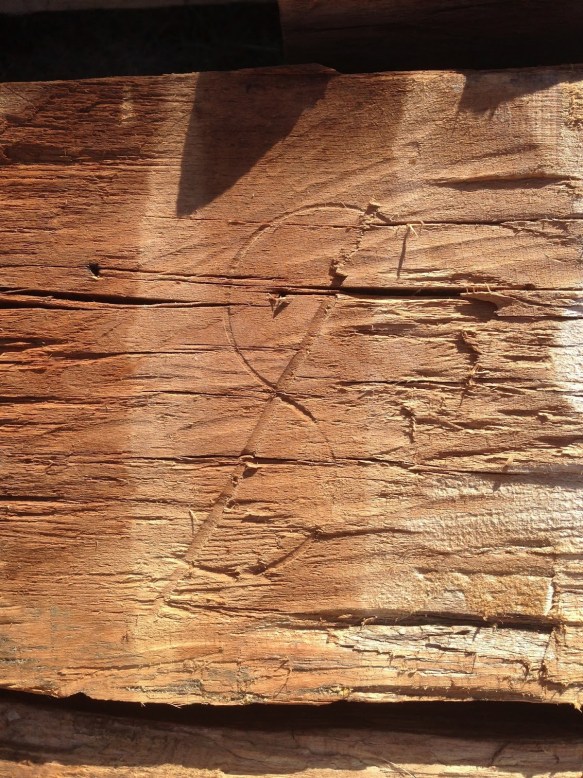

The gambrel has a unique system where the floor girts and joists went out beyond the eve to create an overhang. Heavy planks rested on the joist tails. Here is a photo of the labeling of those planks: Another beautiful inscription was often placed on a central board in the ceiling. This photo is one of these daisy wheels:

Another beautiful inscription was often placed on a central board in the ceiling. This photo is one of these daisy wheels: We re-label each joint as we take it down. Occasionally, in the excitement of disassembly, we miss a piece or even mis-label. When we are stumped, we often look for the original labels and figure out where it will be “at home.”

We re-label each joint as we take it down. Occasionally, in the excitement of disassembly, we miss a piece or even mis-label. When we are stumped, we often look for the original labels and figure out where it will be “at home.”

Pragmatic & Beautiful

These old labels are both useful and artistic. They were created using very sharp chisels, often of a “gouge” or cupped variety, as well as compasses. The labels add beauty to the finished space when visible. As with all aspects of vintage frames, much can be learned about the people who crafted the barns or homes by looking at their “handwriting.”

Some label inscriptions are flowery and large; others are more subtle and small, meant to disappear visually once the frame is up.

Below is a brace and post from the North Hero barn:

This builder used much smaller labels and a different marking

How did the framers come up with these markings, and are they universal?

We do not know how the craftsmen from the past decided on the specifics of their labeling systems. The pragmatic aspect of the labels means that each frame contains its own logic. That is to say, it is a self-contained system that can differ frame to frame. We are just grateful when we see the labels match each other on each joint and we know we’ve put the pieces back together correctly! We like to imagine the framers carefully making the inscriptions generations ago, and we are grateful for the artistic care represented in these labels!

Here is one of my favorites – a label designating a second floor post and brace on the gambrel:

Have you seen labels on pieces of your house?

Please let us know what you might know about old labeling systems! In particular, we are curious if anyone has seen the representation of 11 that we’ve shown on the gambrel floor joist. We’d love to hear from you.

Green Mountain Timber Frames specializes in restoring historic timber frames and old barn homes. Interested in more information?

We’d love to hear from you!

(802) 774.8972

Luke@GreenMountainTimberFrames.com

So how does one know where to put each piece of wood?

So how does one know where to put each piece of wood?

Note the four slashes, and the one slash with an additional diagonal cut. The opposite wall does not have the diagonal marking.

Note the four slashes, and the one slash with an additional diagonal cut. The opposite wall does not have the diagonal marking.